- Hidden Codes in 3D Prints: Researchers at Washington University in St. Louis have developed a method to embed unique digital “fingerprints” into 3D-printed parts. The system, called Secure Information Embedding and Extraction (SIDE), can encode data like timestamps, printer IDs, geolocation, and owner info directly into the object’s structure engineering.washu.edu 1 .

- Traceable Even if Shattered: Unlike earlier marking methods, these fingerprints are break-resilient and tamper-tolerant. Even if a printed object is smashed to pieces, a fragment can yield identifying information. The embedded markers remain detectable in fragments, allowing forensic investigators to retrieve the hidden code from a piece of the object tomshardware.com 2 .

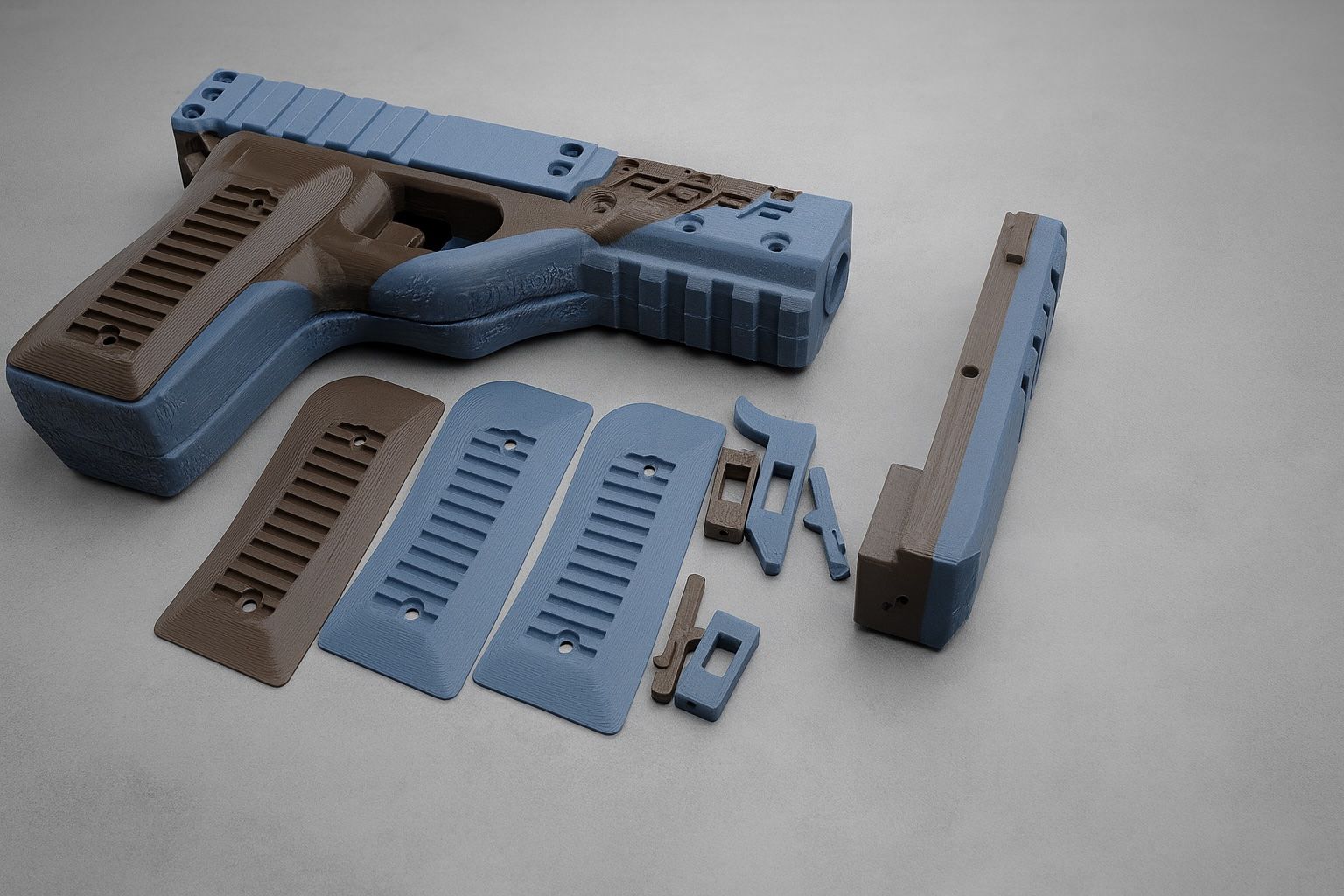

- Aimed at Ghost Guns: A key motivator is the rise of “ghost guns” – untraceable firearms made with 3D printers. The new technique could make it easier to track homemade 3D-printed weapons, linking a confiscated gun part back to the printer (and potentially person) that made it tomshardware.com 3dprintingindustry.com. Law enforcement sees traceable 3D prints as crucial for cracking down on illicit weapon manufacturing.

- Who’s Behind It: The SIDE framework is being developed by Netanel Raviv and his team at WashU’s McKelvey School of Engineering. The work was presented at the USENIX Security Symposium in August 2025 and builds on earlier research into recovering data from broken 3D-printed parts engineering.washu.edu engineering.washu.edu. The project is backed by the U.S. National Science Foundation and Army Research Office 3 .

- Compared to Other Methods: This digital fingerprinting goes further than existing 3D print tracing techniques. Traditional approaches include analyzing toolmark patterns left by specific printers or using AI to identify a printer’s “signature” from tiny imperfections tomshardware.com fabbaloo.com. Others have tried visible QR codes, RFID tags, or tiny surface bumps, but those can be physically removed ar5iv.labs.arxiv.org ar5iv.labs.arxiv.org. SIDE’s embedded code is covert and designed to survive damage that would defeat these older methods techradar.com 4 .

- Benefits and Controversy: Proponents say digital fingerprints could protect public safety by deterring criminal use of 3D printers 3dprintingindustry.com and help industry by authenticating parts (preventing counterfeit or substandard 3D-printed components in supply chains). However, the idea is raising privacy and legal questions. If regulators mandate such fingerprinting on all printers, hobbyists worry about surveillance and loss of anonymity in personal manufacturing techradar.com techradar.com. There are also practical challenges—determined attackers could still bypass or strip out the fingerprints, especially on open-source 3D printers tomshardware.com 5 .

Introduction: Ghost Guns and Digital Fingerprints

3D printing has opened the door to amazing innovations – custom tools, spare parts, even artistic creations – but it also has a dark side. In recent years, hobbyist 3D printers have been used to produce unregistered, untraceable firearms known as ghost guns. These DIY weapons lack serial numbers and skirt traditional gun regulations, making them appealing to criminals. A chilling example came in late 2024, when a ghost gun was implicated in the murder of a healthcare executive engineering.washu.edu engineering.washu.edu. This incident underscored why law enforcement is anxious about ghost guns: they’re effectively invisible to normal tracing methods.

In response to this threat, researchers have been looking for ways to tag or identify 3D-printed objects – essentially giving them a “fingerprint” that ties them back to their source. Now, a breakthrough from an interdisciplinary team at Washington University in St. Louis promises exactly that: a method to embed digital fingerprints into 3D-printed parts, making even shattered pieces traceable engineering.washu.edu engineering.washu.edu. This technology, dubbed Secure Information Embedding and Extraction (SIDE), could fundamentally change how we track and authenticate 3D-printed items. From ghost guns to counterfeit machine parts, digital fingerprinting may foil those who rely on 3D printing’s anonymity.

What Is a “Digital Fingerprint” in 3D Printing?

In the context of 3D printing, a digital fingerprint is a hidden code or identifier that is embedded into the physical object as it’s being printed. Think of it as steganography for physical items – invisible to the naked eye but encoded in the object’s internal structure or surface in a way that can be later read by investigators or authorized personnel. According to the WashU team, their method can integrate data like printer serial numbers, the owner’s ID, time stamps, and even geolocation coordinates of where an item was printed engineering.washu.edu engineering.washu.edu. This information lives within the plastic (or resin/metal) of the item itself.

How can data hide in a solid object? There are multiple techniques researchers have explored over the years: for example, varying the width of printed layers or infill patterns to represent bits, adding tiny internal voids or bumps in a pattern, or subtly altering print parameters like speed or orientation to encode information ar5iv.labs.arxiv.org ar5iv.labs.arxiv.org. One prior study described encoding bits by using slightly thicker vs. thinner layers in certain regions of a print ar5iv.labs.arxiv.org. Another approach embedded microscopic physical tags (like RFID chips or QR code patterns) inside objects ar5iv.labs.arxiv.org. The concept isn’t entirely new – in fact, 2D paper printers have long included hidden yellow dot patterns as fingerprints to identify which printer produced a page, a practice quietly used since the 1980s tomshardware.com tomshardware.com. The challenge has been translating such fingerprinting to 3D-printed items, which can be more complex and are often subject to deliberate tampering.

The SIDE framework developed by Raviv’s team is essentially a sophisticated implementation of this idea. While the exact method is tightly guarded (understandably, to prevent giving bad actors a blueprint to defeat it), the researchers describe it as a combination of mathematical encoding techniques and security mechanisms built into the printer’s operation engineering.washu.edu engineering.washu.edu. In simple terms, SIDE would compel a (cooperative) 3D printer to introduce a unique code into every object it fabricates. The code might be distributed throughout the object so that even a small fragment contains some of the data. Crucially, SIDE emphasizes robustness: it uses “break-resilient, loss-tolerant embedding” so that the fingerprint can survive attempts to destroy or mutilate the object 3dprintingindustry.com 3dprintingindustry.com. As Raviv explained, the goal is to ensure that even if an adversary breaks the printed part into pieces, investigators can still extract the embedded information without needing to reconstruct the whole item tomshardware.com 6 .

How the Technology Works – Inside the SIDE Framework

The Secure Information Embedding and Extraction (SIDE) framework is at the heart of this new tech. It builds on earlier research presented at an IEEE symposium in 2024, where Raviv’s group showed it was mathematically possible to recover data from fragments of a 3D print that had been deliberately broken engineering.washu.edu engineering.washu.edu. Now, SIDE takes that a step further: not just recovering data, but actively embedding a chosen fingerprint into the object during printing.

While the researchers haven’t publicly detailed the proprietary “recipe” for SIDE, they have given general insights. The system likely involves:

- Firmware/Software Control: SIDE requires modified printer firmware or slicing software that introduces slight, patternized variations corresponding to the data bits. These variations could be in layer thickness, infill spacing, micro-void placement, or other print settings that won’t visibly mar the object but can be detected with the right tools ar5iv.labs.arxiv.org ar5iv.labs.arxiv.org. Essentially, the printer is “compelled” to include the code in each object it makes 3dprintingindustry.com 7 .

- Mathematical Encoding (Error Tolerance): The data is encoded with redundancy and error-correcting codes so that if parts of the print (and thus parts of the code) are missing or damaged, the message can still be decoded from what remains 3dprintingindustry.com 3dprintingindustry.com. This is analogous to how a music CD can play correctly even with some scratches, thanks to error correction. In the context of 3D prints, the “noise” or damage could be a chunk of the object being gone – SIDE’s code is designed to handle that.

- Security Measures: The team mentions new security mechanisms to enforce the embedding engineering.washu.edu. This implies the system might have protections against someone easily disabling it. For instance, it might be baked into the printer’s closed-source firmware or require cryptographic signing of print jobs so that the fingerprinting can’t be removed without detection. The exact details aren’t public, but the intent is to make it non-optional on a given printer – a would-be criminal can’t simply flip a switch to turn off the fingerprinting if they’re using a regulated printer.

Netanel Raviv summarized the significance of their approach, saying: “This work opens up new venues for protecting the public from the harmful aspects of 3D printing via a combination of mathematical contributions and new security mechanisms.” But he also acknowledged limitations, noting that SIDE can be defeated by truly resourceful, expert adversaries, and thus mainly “raises the level of sophistication, prior knowledge and expertise required from the adversary to remain undetected” engineering.washu.edu engineering.washu.edu. In other words, it’s about making it a lot harder – not impossible – for someone to produce untraceable prints. A casual hobbyist-turned-criminal might be deterred or tripped up by built-in fingerprints, whereas a highly skilled operator could still find ways around it (more on that below).

For forensic use, investigators would need a way to read the fingerprint. Depending on how it’s embedded, this could involve imaging the object’s internal structure (e.g., using a microscope, CT scan, or even just a smartphone camera if the pattern is on the surface) and then running a decoding algorithm to extract the hidden message. The researchers have indicated that only a fragment of the object is required – for instance, TechRadar noted the system allows “fragments to retain enough encoded detail for investigators to recover key information” techradar.com techradar.com. This was demonstrated in tests where even a small piece of a broken 3D-printed gun frame could be analyzed to reveal the fingerprint code tomshardware.com tomshardware.com. Such capability is a game-changer for crime scenes: a culprit might attempt to destroy a 3D-printed weapon or tool thinking it will cover their tracks, but a piece left behind could still “whisper details of its origin” to forensic experts techradar.com 8 .

Applications and Use Cases

Tracing Ghost Guns and Illicit Weapons

The immediate application for digital 3D-print fingerprints is in criminal forensics, specifically targeting ghost guns. Law enforcement agencies have struggled with a surge in homemade firearms that lack serial numbers. If a gun or gun component (like a 3D-printed frame or receiver) is found at a crime scene, currently there’s often no way to trace it back to who printed it – no markings, no paper trail. With the SIDE technology, that could change dramatically. Each printed part would carry an indelible mark of its origin, allowing police to potentially identify which printer (and therefore which owner) made the gun part and when tomshardware.com engineering.washu.edu. This could lead investigators to illicit workshop operations or online file distributors.

In fact, earlier this summer, a forensic specialist from California, Detective Kirk Garrison, revealed that standard 3D printers already leave behind subtle “toolmarks” – microscopic patterns from the nozzle and print process – that helped him link ghost gun parts to specific printers in some cases tomshardware.com tomshardware.com. Those findings, however, relied on fortuitous, unintentional signatures and had limitations. Garrison’s method involved using a microscope to find “scuff marks in a repeated pattern” on printed gun parts, and he observed consistent quirks from the same printer model tomshardware.com tomshardware.com. It was enough to narrow down suspects, but not enough to pinpoint a single printer with certainty tomshardware.com. The technique also struggled if the object’s surface was smoothed or if printing conditions changed tomshardware.com 9 .

Digital fingerprints like SIDE would augment or replace such guesswork with a deliberately planted identifier. It’s the difference between finding a unique scratch and finding a hidden serial number. Authorities envision that if ghost guns become routinely fingerprinted, it would take away a key incentive for using them – the anonymity. Even if a criminal tried to obliterate the code (say, by melting the plastic or sanding the surface), the data could still be recovered from internal fragments tomshardware.com tomshardware.com. And if they somehow completely destroyed the item (e.g. by burning or grinding it to dust), that weapon is gone from the scene anyway – but crucially, they would have had to go to extreme lengths, possibly drawing attention or limiting their own use of the weapon.

It’s worth noting that governments are already moving to curb ghost guns through other means. In the U.S., new federal rules now require commercial “gun kit” sellers to include serial numbers and buyers to undergo background checks, closing a loophole on partly-finished frames. Several states (like New York) have introduced or passed laws specifically banning 3D-printed guns or requiring any homemade firearm to be registered. New York’s Attorney General, for instance, teamed up with legislators on a bill to crack down on 3D-printed guns and even 3D-printed auto sears (devices that convert guns to full-auto) 3dprintingindustry.com 3dprintingindustry.com. If such laws expand, one could imagine a future requirement that all 3D-printed gun components contain an authorized fingerprint. A digital fingerprinting system might thus become a regulatory tool – e.g., only allowing sales of 3D printers that implement approved fingerprinting, making it legally punishable to disable it when printing firearms.

However, this raises a complex enforcement question: 3D printing is decentralized. Unlike licensed gun manufacturers, hobbyist printers are everywhere and the machines themselves can be modified. We’ll dive into the challenges and controversies in a later section, but it’s clear that from a technical standpoint, tools like SIDE would give law enforcement a much-needed edge in a game of cat-and-mouse with ghost gun makers.

Beyond guns, consider other contraband or restricted items. 3D printing has been used for making things like counterfeit keys, burglary tools, or banned devices. Digital fingerprints could similarly help trace those. If a 3D-printed counterfeit ATM skimmer or a fake key for an expensive car is found, the hidden code might reveal which printer (and thus which lab or home) produced it. This could extend forensic capabilities into areas of cybercrime and theft that involve 3D-printed gadgets.

Supply Chain Authentication and Anti-Counterfeiting

Outside of law enforcement, industry has a big stake in 3D-print traceability too. As additive manufacturing (AM) is increasingly used for production parts – in aerospace, automotive, medical implants, etc. – companies want to ensure that parts are genuine, safe, and produced to spec. Counterfeiters might use 3D printing to replicate parts and pass them off as originals, or a rogue supplier might cut corners. Digital fingerprints could act as an authentication seal.

For instance, a jet engine manufacturer could require that every 3D-printed component (like a turbine blade or a nozzle) contains a fingerprint encoding the factory and batch. Later, a routine maintenance scan of the part could decode the fingerprint to verify it’s an officially made part and not a knock-off. This kind of authenticity check is analogous to scanning a QR code, but done invisibly via the part’s internal structure.

Interestingly, a team in Germany at the Federal Institute for Materials Research (BAM) recently demonstrated another approach to this problem: they leverage the natural random microstructure of 3D-printed metal parts as a fingerprint, scanning them with micro-CT (computed tomography) to get a unique pattern that is linked to a digital record bam.de bam.de. Because each print has slight material variations, it’s like a physical unclonable fingerprint. That method doesn’t intentionally embed data, but rather reads the part’s innate “grain” as an ID. One advantage is it requires no changes to the printing process – nothing to insert, and nothing obvious to remove. “Our method does not require any visible markings or intervention in the printing process,” said Anja Waske of BAM, adding that it opens new possibilities for product verification and plagiarism protection in industry bam.de 10 .

The SIDE approach, by contrast, is an active fingerprint: it injects known information rather than relying on randomness. Both approaches could complement each other. For example, SIDE could encode a part’s official ID, while a scan of its microstructure could verify that it hasn’t been swapped or altered since manufacture.

We should also mention intellectual property (IP) protection. 3D printing blurs the lines of IP because distributing a CAD file can lead to anyone printing a patented or copyrighted object. While fingerprints won’t directly stop unlawful printing, they could help in legal enforcement. If a company finds an unauthorized vendor selling 3D-printed copies of their product, a hidden fingerprint in the items could prove those came from a specific printer (or batch) not licensed by the company. This could serve as evidence in court or help track the source of leaked design files. It’s analogous to a watermark on digital media, but physically embedded in the object.

Additionally, manufacturers might use fingerprints for quality control. Suppose a batch of 3D-printed medical implants is found to have defects; by reading the fingerprint, the company could quickly figure out which machine and settings were used, and identify other parts that might be affected. In fact, earlier research by University of Illinois engineers in 2023-2024 discovered that every 3D printer has unique output variations, to the point that an AI system could identify which machine made a given part with 98% accuracy from just a 1mm² sample of the surface fabbaloo.com fabbaloo.com. “Each one of these parts has a unique signature that can be detected using AI,” said UIUC’s Prof. Bill King fabbaloo.com fabbaloo.com. That concept was initially proposed for monitoring production consistency and spotting if a supplier switched machines. Now, with deliberate digital fingerprints, one could ensure that even if two parts look identical and perform identically, their origin can still be distinguished. This could be a powerful deterrent against mixing in counterfeit parts or violating production licenses.

Consumer and Commercial Product Tracking

Imagine a future where everything coming out of a 3D printer has an invisible barcode of sorts. This could streamline product recalls (“scan the item’s fingerprint to see if it was part of the recalled batch”), recycling processes (“identify the material composition and origin for proper recycling”), and even consumer rights (“prove that you did print that spare part under a valid license”).

Some 3D printer makers are exploring secure printing ecosystems. For example, Ultimaker (a major 3D printer brand) recently introduced a line of “secure” printers that restrict connectivity for IP protection. One could envision them incorporating fingerprinting so that any object printed on them is tagged as an Ultimaker-produced item, which companies might prefer for certified manufacturing.

However, such pervasive tagging also starts sounding a bit like DRM (Digital Rights Management) for the physical world, which many consumers and makers push back against. This leads us into the broader discussion of implications and controversies.

How Does It Compare to Other Tracking Methods?

To better appreciate the novelty of digital embedded fingerprints like SIDE, let’s compare them with other 3D-print tracking and firearm tracing methods:

- Forensic Toolmark Analysis: As mentioned, investigators like Det. Garrison rely on examining a printed object for characteristic marks (striations, patterns) left by a specific printer’s hardware. This is analogous to ballistic fingerprinting in traditional firearms, where forensic labs match bullets or casings to a gun by the microscopic scratches from that gun’s barrel or firing pin. It requires no special cooperation from the printer or user – the marks happen naturally – but it’s often not conclusive. Different printers of the same model might produce similar marks, and factors like filament type or print orientation can alter the pattern. Moreover, a criminal can sand or polish a printed part’s surface to obscure these marks tomshardware.com tomshardware.com. Toolmark analysis is a great investigative lead (it can group parts as having a common source) but rarely a smoking gun on its own. Digital fingerprints would be a step up: deliberately engineered markers that encode definitive info (e.g., a serial number) rather than just “matching patterns.”

- Machine Learning “PrinTracker” Approaches: Researchers have trained AI models to identify the printer make/model (and even the specific unit) from images of a printed object’s surface. The UIUC study by King’s group is one example, which essentially built an AI classifier for printer signatures fabbaloo.com fabbaloo.com. Another earlier project called PrinTracker (by University at Buffalo in 2018) used a similar idea, achieving high accuracy in matching parts to printers using digital microscopy images. These methods exploit tiny deviations – think of them as the 3D printer’s “ballistic fingerprint.” They are promising for forensic use because they again require no cooperation from the offender. But they also share the weaknesses of toolmarks: they can be fooled by modifying the object’s surface or by recalibrating the printer. They also might struggle if the object is fragmented; most require an intact surface section for imaging. In contrast, SIDE’s embedded codes are designed to be fragment-readable and less sensitive to surface finishing tomshardware.com tomshardware.com. If part of the code is lost, redundancy helps recover it.

- Physical Tags (RFID, QR codes, Serial Numbers): The most straightforward way to mark a part is to literally slap an identifier on it – e.g., print a QR code on the object’s exterior, or embed an RFID chip inside it, or engrave a serial number after printing. While effective in controlled settings, these are obvious and easily defeated. A QR code or engraved number can be ground off. An RFID tag can be located and removed (or the chip could be destroyed by a microwave). And obviously, anyone printing a ghost gun isn’t going to voluntarily stick a serial number on it. These methods also might not survive intentional destruction: if you shatter a printed part, the section with the visible code might be gone. In fact, the existence of SIDE is to answer the question: “what happens when a printed object is broken into pieces or deliberately tampered with?”, a scenario where previous approaches failed techradar.com techradar.com. By embedding the code throughout the object (not just on one label or chip), SIDE ensures part of the code is in every fragment – you’d have to destroy all pieces beyond recognition to eliminate the fingerprint.

- Digital File Watermarking: Another angle is marking the digital design (CAD or STL file) for a part. Some companies have proprietary formats where they can include metadata about the print, or even slicer software that can introduce a known pattern (watermark) into any print from a given file. For example, a designer might intentionally include a small unique emblem in the 3D model to claim authorship. However, as commenters on the Tom’s Hardware forum pointed out, if the fingerprint is in the model, “all prints will have the same fingerprint” which doesn’t help trace who printed it tomshardware.com tomshardware.com – it only shows it came from that model file. And a savvy user can simply modify the file slightly (scale it 1% or re-export it) to “fuzz” out any watermark tomshardware.com tomshardware.com. So file-based watermarks can be removed or might only prove the lineage of the design, not the printer.

In summary, SIDE’s embedded fingerprint is like an internal serial number that travels with the object through destruction, whereas other methods either rely on external markings or incidental signatures that are easier to obliterate. One could combine multiple methods for greater assurance: e.g., have printers embed SIDE codes and use an AI fingerprint check on recovered parts. Indeed, TechRadar mused that combining such invisible fingerprints with AI pattern recognition could allow investigators to “reconstruct timelines and identities from fragments of plastic or resin” techradar.com techradar.com – a forensics dream scenario.

Challenges and Limitations

No technology is foolproof, and digital fingerprinting of 3D prints is no exception. Several technical and practical challenges could limit the effectiveness of SIDE or similar systems:

- Evasion and Defeat by Users: A determined user could attempt to disable or bypass the fingerprint embedding. For instance, if the printer’s firmware is open source (as many hobbyist 3D printers’ firmware are), a knowledgeable person could modify the code to turn off SIDE or compile an older firmware version without it tomshardware.com tomshardware.com. Unlike paper printers, which have long been closed systems, the 3D printing community values open control – meaning it’s feasible to run a printer “offline” from any mandated features. As one critic noted, “3D printers are an entirely different market [than 2D], where printers that are open-source or can have open source firmwares flashed are the norm. If you ask the targets to kindly run your firmware that fingerprints their prints for you, you will simply be told ‘no’.” tomshardware.com tomshardware.com This suggests that unless fingerprinting is somehow made unavoidable (through hardware or legal controls), criminals will simply print without it.

- Physical Removal or Damage: If someone knows their printed object might have a hidden code, they might try to physically alter the object post-print to destroy the code. The easiest way could be to re-melt or remelt the surface – e.g., using a heat gun or acetone vapor (for ABS plastic) to smooth out any subtle layer variations, potentially scrambling the encoded bits. A commenter on the Tom’s forum wryly observed that “running a heat gun on the surface to flow it just a touch would alter things enough to make it completely untraceable” tomshardware.com tomshardware.com, or even a quick sanding pass. However, the WashU team anticipated tampering, which is why the fingerprint is meant to be robust. Even if you partially melt or sand, unless you perfectly homogenize the entire piece (which might destroy it or its functionality), fragments of the original encoding likely remain internally. Still, extreme methods like completely melting and recasting the plastic would obliterate the structured code – but at that point, the object is no longer the same functional item (a melted gun frame can’t shoot).

- Structural Integrity Concerns: One worry is whether embedding a code could weaken the part. If the fingerprint requires certain patterns (like tiny voids or irregular layer widths), could that make a gun frame more prone to cracking, for example? The researchers haven’t fully disclosed the impact on strength. They claim the markers are designed to be “secure against manipulation” without significant intervention in the printing process bam.de bam.de, implying it shouldn’t drastically change the part’s integrity. But it’s a fine line: robust encoding might call for redundant markers, which means introducing multiple small anomalies in the print. If overdone, those could act as stress concentrators in mechanical parts. Part of the ongoing research is likely testing how much they can embed data without compromising the item’s performance or appearance.

- Data Capacity and Complexity: How much information can you realistically embed in a single print? Likely not a ton – perhaps a few bytes to a few kilobytes at most without the changes becoming noticeable. For forensic purposes, you really only need a unique ID that can be looked up in a database to fetch the details (owner, printer, etc.). That could be just a numeric code. But ensuring that code is spread across the object for redundancy and can survive breakage means a lot of engineering. There’s a trade-off between fingerprint complexity vs. detectability: a more complex code might be easier to detect if one knows what to look for, whereas a very subtle code might not carry much info. The WashU team’s academic paper dives into the coding theory of this “torn-paper channel” problem ar5iv.labs.arxiv.org ar5iv.labs.arxiv.org, treating the broken object like pieces of a torn paper that need to still contain the message. They reportedly achieved optimal or near-optimal solutions in terms of redundancy ar5iv.labs.arxiv.org ar5iv.labs.arxiv.org, but in practice, this will constantly evolve as printers and materials change.

- Adoption and Standardization: For this tech to make a real difference, it needs adoption by either 3D printer manufacturers or regulatory bodies (or both). Manufacturers might be hesitant to implement fingerprinting unless required, because it adds complexity and could become a “feature” that some customers don’t want. Indeed, there’s a segment of the maker community that would find this idea hostile – much like how some people resisted DRM in other tech. Without broad adoption, criminals could simply use a printer model that doesn’t implement fingerprinting. If only a few brands do it, the bad guys will avoid those. Governments could mandate that “any 3D printer sold must include approved fingerprinting,” but enforcing that globally (or stopping the flow of kits and old machines) is quite difficult. It’s telling that Raviv’s quote explicitly notes SIDE’s limitations “in defending against resourceful attackers with strong expertise in 3D printing” engineering.washu.edu engineering.washu.edu – in other words, the very people likely making ghost guns might be the ones with enough know-how to circumvent consumer-level protections.

- False Sense of Security: A policy risk is that authorities might overestimate what fingerprinting can do. If a ghost gun is used and completely destroyed (say, ground into plastic shavings or melted in a fire), no technology can retrieve a fingerprint from ashes. Criminals might adapt by moving from partial destruction (which SIDE defeats) to total destruction or using materials/printing methods that don’t support fingerprinting. Additionally, if someone steals a fingerprinted printer or builds one from scratch, the trace might lead to a dead end or innocent identity. For example, if a fingerprint encodes the printer owner’s ID, a criminal could hack a printer to embed someone else’s ID (a form of framing). These are theoretical, but any forensic measure has to consider being fooled or misled.

Legal and Ethical Implications

The notion of embedding mandatory identifiers in 3D prints raises important legal, ethical, and privacy questions. It’s a classic duel between public safety and personal freedom:

On the one hand, lawmakers and law enforcement see digital fingerprints as a boon. With ghost gun crimes on the rise, there’s public pressure to “do something.” Digital fingerprinting could be that “something” — a technological fix that makes it easier to solve gun crimes and maybe dissuades people from printing guns in the first place (if they know it won’t be as untraceable as they thought). Governments have already mandated things like microstamping for firearms in some jurisdictions (e.g., requiring firing pins to imprint a tiny code on bullet casings). Mandating a 3D printer fingerprinting feature could be viewed similarly – a safety requirement. If widely implemented, it might even allow a new category of regulation: perhaps homemade guns could be legal if they contain traceable fingerprints registered to the maker, and illegal otherwise.

However, the opposition from gun rights and maker communities would be strong. Organizations like the Firearms Policy Coalition argue that sharing 3D-print gun files is a form of free speech, and that attempts to ban or track them infringe constitutional rights. When Facebook banned 3D gun instructions on its platforms, the FPC objected, proclaiming “Information is code. Code is free speech. Free speech is freedom.” 3dprintingindustry.com 3dprintingindustry.com. That ethos extends to hardware – forcing fingerprinting could be seen as forcing a form of surveillance into everyone’s personal 3D printer. Today it’s guns, but tomorrow will every thing you print be traceable back to you in a database? Privacy advocates might raise alarms that this creates a potential for monitoring hobbyists or suppressing innovation. After all, 3D printers are general-purpose tools; many would balk if told their printer must report or embed an ID for every trinket, cosplay prop, or household fix they fabricate.

Legally, implementing this could be tricky. Would it mean all new printers must have licensed firmware that users are forbidden to tamper with (much like how cable TV boxes were sealed)? That could clash with right-to-repair and open-source licenses. And what about existing printers – millions of them – that have no such capability? There would be a long tail of unfingerprinted devices in circulation. Perhaps authorities might focus on commercial and industrial printers or those used in public makerspaces first.

Ethically, there’s also the question of scope creep. If a technology is installed ostensibly to fight crime, could it be used for other monitoring? For example, could a company require that all designs printed on its machines carry a fingerprint that phones home to verify if you had paid for that design? (One could imagine DRM where a fingerprint verifies the object was printed from a legitimately purchased file, otherwise it’s tagged as contraband.) This crosses into IP enforcement in ways some find uncomfortable – essentially licensing every print.

Furthermore, consider countries with repressive regimes: if all 3D prints carry a fingerprint, it could be used to track dissidents who 3D-print protest materials or tools for civil disobedience. Or perhaps you live in a place where printing certain shapes (like encryption devices or even art that offends the government) is illegal – fingerprints would make it easier to catch you. These are not far-fetched concerns; they mirror debates in software backdoors and encryption keys.

From a global perspective, even if one country implements strict rules, others may not. Someone could print illicit items in a jurisdiction without fingerprint mandates and smuggle them. It’s akin to how ghost gun kits flow from states with looser laws to stricter ones. An international standard or treaty would be needed to truly universalize it, which is a tall order.

The ethical balance comes down to: Will digital fingerprints in 3D printing do more good by improving safety, or more harm by eroding privacy and user rights? Many experts say it doesn’t have to be either/or. For high-risk items like guns or critical aircraft parts, fingerprinting might be justified. For personal, harmless creations, perhaps it remains voluntary. The TechRadar piece encapsulated this tension, noting that while fingerprinting could thwart illicit weapons, “this raises questions about the scope of surveillance, control over personal manufacturing, and the balance between security and privacy.” techradar.com techradar.com If, for example, hobby 3D printers were required to include these systems, it essentially treats every user as a potential criminal – something many would object to. Policymakers will have to navigate these waters carefully, possibly carving out exceptions or ensuring anonymity unless a crime is committed and an object is retrieved.

Expert and Industry Commentary

The concept of embedding fingerprints in 3D prints has drawn commentary from technologists, law enforcement, and industry leaders:

- Netanel Raviv (Lead Researcher): Raviv is understandably optimistic about his team’s work. He emphasizes that it “opens up new venues for protecting the public from the harmful aspects of 3D printing”, while conceding it’s not a panacea against skilled adversaries engineering.washu.edu. His goal is raising the bar. In interviews, he’s highlighted how this could give investigators critical leads (printer ID, owner, time/place) that were previously unattainable from a piece of plastic 3dprintingindustry.com 3dprintingindustry.com. By coupling math and security, he envisions a future where a 3D-printed gun found at a crime scene is no more anonymous than a registered commercial firearm.

- Forensic Experts: Those on the front lines of ghost gun investigations, like Detective Garrison, see promise but also caution. Garrison’s initial experiments with identifying prints via toolmarks showed that there is a fingerprint of sorts already, but he likely would welcome a more reliable built-in marker. However, he might warn that criminals will try countermeasures. His observation that a quick heat treatment or sanding could foil simple marks tomshardware.com tomshardware.com underscores why the fingerprint must be deep and redundant. The fact that he collaborated with researchers (from University of Oklahoma per 404 Media) suggests law enforcement is actively looking to science for solutions on this issue.

- Academics and Industry Researchers: Professor Bill King of UIUC, who worked on AI identification of prints, hailed the discovery of machine signatures as “fascinating”, noting how ubiquitous 3D printers are and that each produced part “has a unique signature that can be detected” fabbaloo.com fabbaloo.com. This independent work provides a nice validation that even without intentional fingerprints, 3D prints aren’t identical. King’s perspective is more on quality control and supply chain integrity – which means he might see digital fingerprints as a complementary tool: AI can catch if something is off, and a digital code can confirm the identity with certainty. Another interesting voice is from the German BAM institute. Project manager Anja Waske touted their non-invasive method, pointing out that it’s “particularly secure against manipulation” because it needs no deliberate markers bam.de bam.de. She and others in that field would likely be interested in how SIDE’s approach could be integrated into a broader authentication framework (like their concept of a “digital product passport” for 3D-printed parts bam.de bam.de). If industry groups and standards bodies (like ASTM or ISO) get involved, we might see official standards for what information gets embedded – e.g. material type, manufacturer ID, etc., in addition to any legal requirements.

- Policy Makers: New York’s District Attorney Alvin Bragg, in pushing state legislation against ghost guns, said he was alarmed by how easily dangerous devices can be made by anyone with a printer 3dprintingindustry.com. While not a direct quote in our sources, the legislative push indicates that officials are actively seeking solutions. If briefed on tech like SIDE, they would likely champion it as a tool to “ensure accountability” for anyone printing firearms. On a federal level, the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) has been tracking ghost gun proliferation; one could imagine ATF officials endorsing digital fingerprinting as analogous to stamping a serial number. The Supreme Court’s recent upholding of ghost gun regulations shows the legal climate might support such measures 11 .

- 3D Printing Community and Advocates: Conversely, many in the 3D printing community are skeptical. Comments on news articles reveal a common theme: “we’ll find a way around it.” One user quipped that if their printer tried watermarking prints, “it will be sold 😅” tomshardware.com tomshardware.com. Others pointed out how DRM in music and software always gets cracked by motivated users, suggesting the same would happen here – “they will use software to strip the fingerprint out… same way they strip DRM outta video games and music files” tomshardware.com tomshardware.com. This cynicism from experienced makers indicates that without community buy-in, fingerprinting might just spawn a new “anti-fingerprint” cottage industry (like tools to randomize your print slightly to erase the code).

It’s also notable that one commenter turned the issue on its head, arguing that ghost guns are a red herring compared to bigger problems: “we can’t seem to track the REGULAR GUNS… maybe we should tackle that problem first… No one is using [plastic guns]” tomshardware.com tomshardware.com. Indeed, to date most gun crimes involve traditional guns, not 3D-printed ones (which are often single-use or less reliable). So there is an argument about resource allocation: is it worth imposing costs or restrictions on 3D printing writ large for a problem that, while growing, is still relatively niche?

The industry will watch pilot cases closely. If a high-profile crime is solved because a 3D-printed part’s fingerprint led police to the culprit, it could sway public opinion toward accepting this tech. Conversely, if there’s a case where a fingerprint is erroneously read or leads to a false accusation (imagine decoding a print fragment incorrectly and pointing to the wrong person), it could sour perceptions and raise civil liberties issues.

Recent Developments and News Coverage

This emerging technology has been making headlines in tech and security circles throughout 2025:

- August 2025: The research was presented at the USENIX Security Symposium (Seattle) and covered in a press release titled “Unique fingerprints in 3D printing may foil adversaries.” TechXplore, a science news site, republished this with context techxplore.com techxplore.com. The presentation and accompanying paper, Secure Information Embedding in Forensic 3D Fingerprinting, laid out the theoretical framework and proof-of-concept results techxplore.com techxplore.com. This caught the attention of cybersecurity and engineering journalists.

- Late August 2025:TechRadar Pro ran an article with the eye-catching headline “Smashing up a 3D printed ghost gun won’t be enough to prevent CSIs from retrieving data” techradar.com. It provided a layman-friendly overview, highlighting the ghost gun angle and raising the broader surveillance debate techradar.com techradar.com. It also explicitly connected the dots to the UnitedHealthcare CEO’s assassination, driving home the real-world stakes techradar.com. This story was syndicated or referenced by other tech outlets, underscoring how digital fingerprints straddle both tech innovation and true crime prevention.

- September 2025:Tom’s Hardware, a mainstream tech news site, published a piece (on Sept 16, 2025) titled “Researchers embed digital ‘fingerprints’ into 3D printed parts — tech may make future ghost guns more traceable.” tomshardware.com. It credited 3DPrintingIndustry.com for initially reporting it, and reiterated the key points: the WashU team’s method can be detected from fragments, and it encodes printer identity and timestamps into the print tomshardware.com tomshardware.com. Tom’s added some historical perspective, noting that 2D printers have hidden identifying dots for decades tomshardware.com, implying that perhaps 3D printers will inevitably follow suit. They also linked back to their July story on Detective Garrison’s toolmark work, giving readers a sense that multiple independent efforts are converging on erasing 3D printing’s anonymity 12 .

- 3D Printing Industry (a specialized industry news site) and others like 3Printr.com ran detailed articles around mid-September 2025, diving a bit deeper into the methodology and including quotes from Raviv. For example, 3DPrintingIndustry’s piece (Sept 15, 2025) stressed that the embedded markers “remain identifiable even if the object is broken” and can reveal “printer used, its owner, and the time and location of printing.” 3dprintingindustry.com 3dprintingindustry.com It also provided valuable context on government and industry responses to 3D printed guns: New York’s legislative actions, the French company Dagoma uploading fake gun files to stymie downloaders, and Facebook’s ban on gun files versus activists’ pushback citing free speech 3dprintingindustry.com 3dprintingindustry.com. This situates the fingerprint tech as part of a larger battle against 3D-printed weapon proliferation.

- Public Discussion: On social media and forums (e.g., Reddit’s 3D printing and gun communities), the news sparked debate. Some praised the ingenuity of the solution; others immediately brainstormed how to defeat it. It became a flashpoint in the ongoing discourse about gun control in the age of digital fabrication. The Reddit thread referencing the Tom’s article had makers pointing out that serious firearm fabricators often use CNC mills or metal, not just plastic printers, and that most 3D-printed guns are lower-quality – implying that the scare, while real, might be somewhat overblown. Still, with metal 3D printing advancing and hybrid approaches (like printing molds for ghost guns), law enforcement isn’t taking any chances.

In the coming months, it will be interesting to watch if any law enforcement agencies start pilot programs using digital fingerprinting, or if any 3D printer manufacturers announce “fingerprinting-ready” models. Also, if any legal cases emerge where a 3D-printed part’s fingerprint is used as evidence, that could set precedent. For now, the research is still in the prototype phase – a very promising prototype.

Conclusion: A New Frontier in 3D Printing Security

The development of digital fingerprints for 3D-printed parts marks a new frontier at the intersection of technology, security, and law. It shows that even as democratized manufacturing tools empower individuals, new checks and balances can arise to address the misuse of those tools. In the near future, the cat-and-mouse game between regulators and rogue makers will likely intensify: will ghost gun builders find ways to stay one step ahead, or will technologies like SIDE rein them in?

For the general public, this innovation carries a double promise. It promises greater safety – the notion that if someone prints a gun and uses it in a crime, they can be traced and caught, which could deter the act altogether. But it also promises that as 3D printing becomes more ubiquitous in producing the parts of our lives (from car components to medical devices), we’ll have ways to verify and trust those parts. A 3D-printed brake pad in your car could one day have a fingerprint proving it was made to spec by the authorized factory, not a counterfeit that might fail.

At the same time, society must tread carefully to avoid unintended consequences. Over-zealous implementation could stifle the creativity and freedom that makes 3D printing so revolutionary. The challenge will be finding the sweet spot where digital fingerprints are used judiciously – targeted at truly critical applications (like firearms or high-stakes industries) – without turning into a blanket surveillance tool for every homemade Yoda figurine and phone case hobbyists print.

What’s clear is that the genie is out of the bottle for ghost guns, and it will take equally ingenious solutions to address it. Embedding hidden codes in plastic might just be one of those solutions. As one headline put it, even a smashed 3D-printed weapon might “still whisper details of its origin” to investigators techradar.com techradar.com. In a world where criminals bank on silence and secrecy, that whisper of data could speak volumes.

Sources:

- Washington University in St. Louis – “Unique fingerprints in 3D printing may foil adversaries” (McKelvey Engineering News) engineering.washu.edu 13

- 3D Printing Industry – “Washington University Team Develops Embedded Fingerprints to Track Ghost Guns and 3D Printed Parts” 3dprintingindustry.com 14

- Tom’s Hardware – “Researchers embed digital ‘fingerprints’ into 3D printed parts — tech may make future ghost guns more traceable” tomshardware.com 6

- TechRadar Pro – “Smashing up a 3D printed ghost gun won’t be enough to prevent CSIs from retrieving data for forensic analysis – here’s why” techradar.com 15

- Fabbaloo – “Researchers Discover Unique ‘Fingerprints’ in 3D Printed Parts Using AI” (UIUC study) fabbaloo.com 16

- Tom’s Hardware – “Police link ghost guns to specific 3D printers using ‘fingerprints’ from printers” (forensic toolmarks) tomshardware.com 17

- BAM (German Federal Institute) – “As unique as a fingerprint: New method makes 3D-printed components traceable” bam.de 10

- 3Printr.com – “Researchers Develop Tamper-Proof Fingerprints for 3D-Printed Objects” 3printr.com 18

- TechXplore – “Unique fingerprints in 3D printing may foil adversaries” techxplore.com 19

- ArXiv (Raviv et al. preprint) – “Break-Resilient Codes for Forensic 3D Fingerprinting” ar5iv.labs.arxiv.org 20